Aluminum Anodizing

Anodizing is a process of electrolytic passivation used on the surface of the metal to increase the thickness of the oxide layer. Aluminum anodizing is a surface hardening process in which electrolytic passivation is used to thicken the layer of oxide that naturally occurs on aluminum alloys.

The anode electrode of an electrical circuit is formed from the treatment which is the process known as anodizing. Paint primers and glues have improved adhesion as well as increased corrosion and wear resistance from the anodizing process which works better than with bare metals. Anodizing can be performed on a variety of metals such as titanium, magnesium, zinc, niobium, hafnium, zirconium, and tantalum anodizing. Aluminum is typically the preferred metal since it is naturally prone to corrosion due to alloying elements such as copper and iron.

Quick links to Aluminum Anodizing Information

History of Aluminum Anodizing

In 1923, oxalic acid anodizing was a chromic-acid based process first used to protect seaplane parts and architectural applications from corrosion. It was first patented in Japan and then used in Germany. In 1927, Gower and O'Brien patented the first sulfuric acid anodizing process.

In the 1960s and 1970s, anodized aluminum was a popular material used for architectural purposes. Since then it has been displaced by less expensive plastics and powder coating. The phosphoric acid processes are the most recent major development. Currently only used as pretreatments for adhesives or organic paints.

Today, the anodizing process is the most common and continues to be developed by industry, and the standards are classified by coating process rather than by process chemistry.

Applications for Anodizing Aluminum

Anodizing does not make the aluminum object stronger. The process increases corrosion resistance, enables dyeing, improves lubrication and adhesion qualities. Aluminum anodizing is utilized by a vast array of applications in industries such as:

- Electronics for protective outer casings for items such as cameras, mp3 players, and satellites.

- Food and beverage for resilient cookware such as pots, mixers, and pans.

- Architecture for structural durability in areas such as window frames, roofs, and exterior surface panels.

- Automotive for aesthetic purposes such as trim as well as the protective housing of exposed parts in auto shops.

- Industrial manufacturing for plant equipment such as scales, electrolytic capacitors, and conveyors.

Anodized Aluminum Process

Anodized aluminum surfaces are harder than aluminum. They have low to moderate wear resistance that can be improved with increasing thickness as well as by applying suitable sealing substances. Anodic films are generally much stronger and more adherent than most types of paint and metal plating, but also more brittle.

The following sub-processes fall into the three main categories:

- Clear Anodize – Type II

- Color Anodize such as black anodizing – Type I, II and III

- Titanium Anodize, which is closely related to aluminum anodizing, is also known for its color variety although it achieves different shades without using dye.

- Type I Anodizing Process

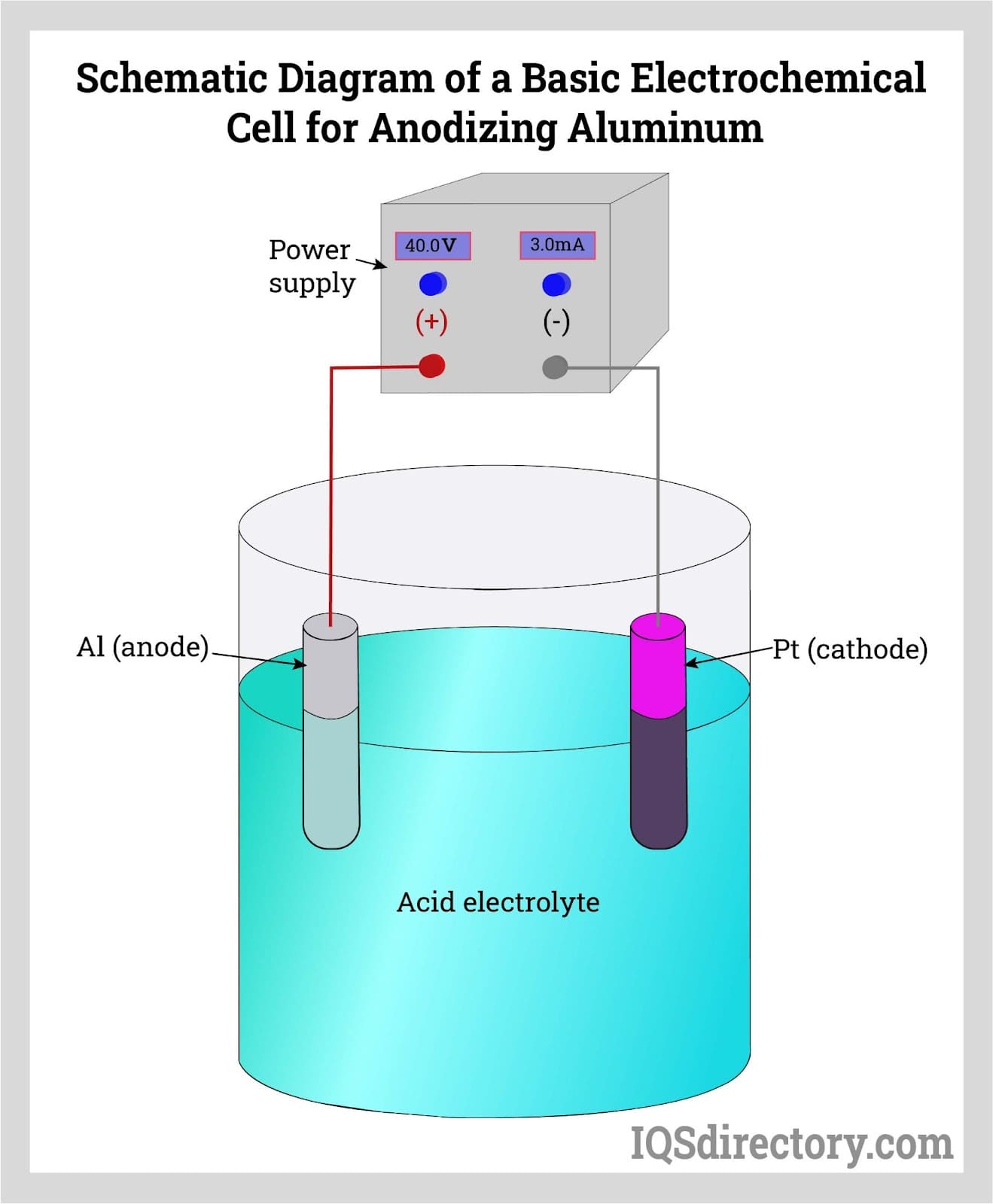

- Type I chromic acid anodizing is the oldest and most common anodizing process. An electrolytic process using chromic acid, which is a corrosive, oxidizing acid compatible with most aluminum alloys. Anodizing occurs when a reactive metal, to which an anode is attached, is immersed in an electrolytic solution and a direct current is passed through the solution. While the anode produces oxygen, creating the oxide film, a cathode attached to the tub filled with solution simultaneously produces hydrogen.

- A downside of the Type I process is that it can reduce the thickness of aluminum by .02 to .4 mils; however, Type II and Type III may reduce the thickness by several times as much.

- In addition, the Environment Protection Agency (EPA) restricts the use of chromic acid emissions because they can be harmful to the environment.

- Type I also differs from Types II and III not only in the type of acidic solution used, but also because in Type I the voltage of the DC is ramped up throughout the process.

- Type II Anodizing Process

- The Type II process is anodized through sulfuric acid. Types II and III both use a sulfuric acid solution, which is a corrosive, dense and oily acid formed from sulfur dioxide.

- Type III Anodizing Process

- Type III is a sulfuric acid hard coat anodized process also known as hard anodizing.Type III differs from Type II in that it is performed at lower temperatures and at a higher electrical current density, which provides increased anodic growth making for a much harder surface.

- Custom anodizing processes are available and are used to achieve other types of anodized metal. Like chromate conversion, some processes have similar methods resulting from anodizing, but still have key factors of difference that separate them, such as retaining electric conductivity or not.

Clear Anodizing

- Uses for Clear Anodizing

- Clear anodizing can be colored by means such as organic dyes and metallic salts to create colors such as red, yellow, blue, and green for decorative applications such as:

- Architecture for use in window and door frames, railings and siding.

- Automotive for use in trim and housings for various exposed parts.

- Printing for use as commercial photolithography plates.

- Industrial manufacturing for sheet metal and various extrusions such as profiles and cases for additional surface protection.

- Jewelry or Artwork.

- Sulfuric acid anodizing process offers better wear resistance than chromic acid anodizing and comparable corrosion and abrasion resistance. Some further benefits of clear anodizing include decreased part maintenance, reduced metal weight, being environmentally-friendly and increased production efficiency.

- Clear Anodizing Process

- The clear anodizing process is identical to the Type II anodizing process. A commonly used anodizing process, Type II sulfuric acid requires the metal to be fully immersed in sulfuric acid, a highly corrosive and oil-like acid that is formed from sulfur dioxide.

- Immersing the metal in the acid, a direct electric current is sent through the sulfuric acid and reacts with anodes on the surface of the material. The reaction of the current and the anodes creates the hard outer film of oxidation.

- The material is then sealed, through the use of hot water, after the material is removed from the acid bath in order to enhance the corrosion-resistant properties of the film. The dye or salt must be introduced after immersion, but before sealing, so that when sealed, the color will become locked in. As beautiful as the color can be, clear anodizing allows the natural luster of the metal to shine through. Although aluminum is the most common material used in clear anodizing, other metals may be anodized as well including titanium, magnesium, zinc, niobium, and tantalum.

Color Anodizing

- Color Anodizing Dying Range

- Color anodizing works well for adding color to metal parts and products because the color will not scratch off. This is because the color is not just applied, the metal itself is dyed. Titanium, zinc, magnesium, and tantalum are metals that tend to take color well. Aluminum and titanium are the most common choices because of their hardness and uses outside of anodizing.

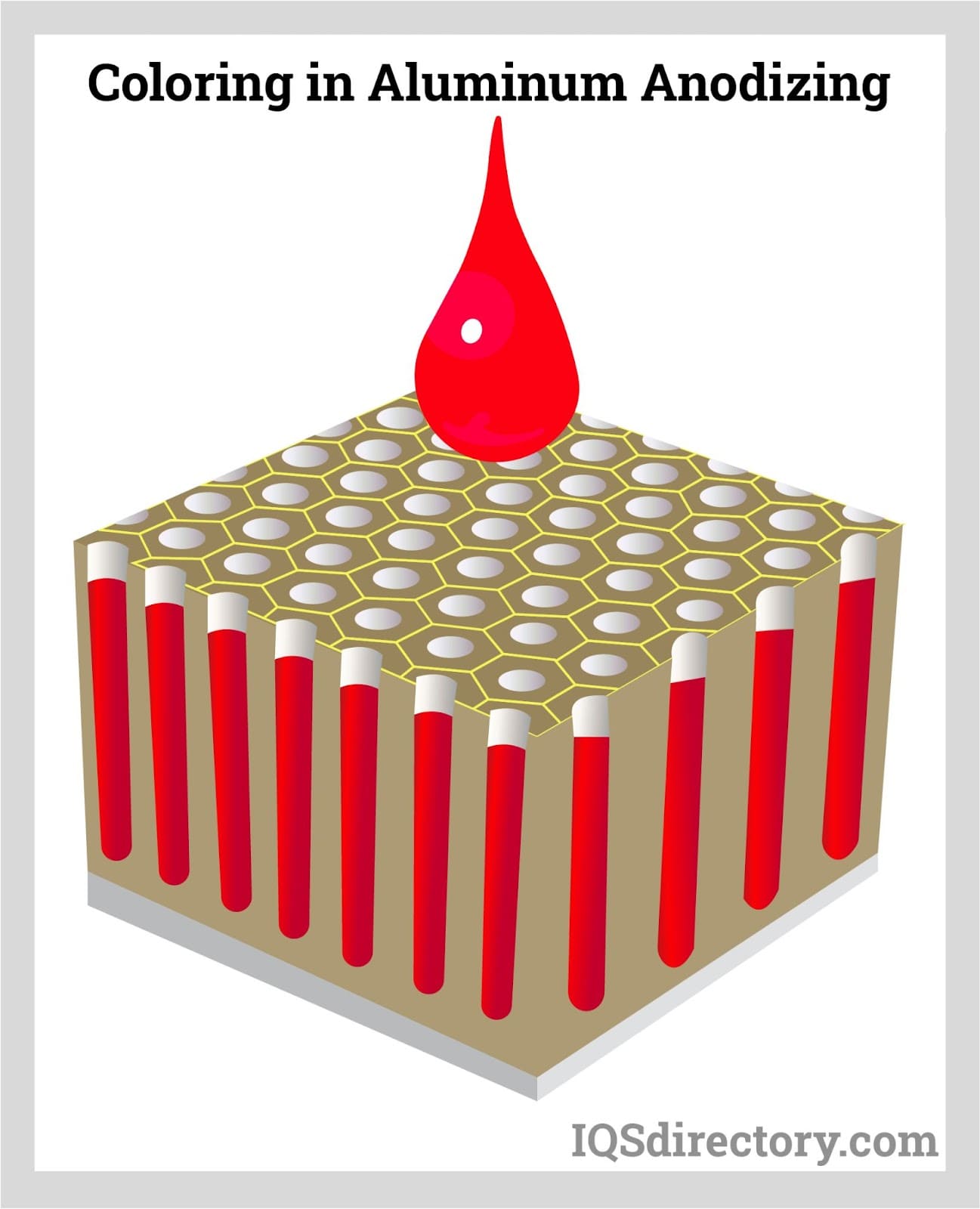

- The oxide surface of a metal can be dyed before the sealing stage of anodization. This is done when the exterior appearance of the product is significant. There are countless dye colors in color anodization. The colors range from light to dark, although lighter colors may be more difficult to manufacture on certain alloys.

- Color anodizing is a favorable process because of the creation of products in many color choices. Color anodized metals have some limitations such as some colors could have more fading than others.

- The result of combining a chemical mixture called ferric ammonium oxalate to an anodized product creates black and gold dyes. This inorganic dye tends to be more lightfast than other colors. Organic colors, which are much more varied, have the downside of being prone to fade. Metallic colors are limited to metallic hues but remain bright longer than either of the first two processes.

- The type of product being produced will also play a part in what color is best. Metallic color processes, for example, are used in the architecture industry. Organic dyes are used in the electronic and construction fields because they work best with aluminum.

- The Process for Color Anodizing

- The actual dying techniques vary depending on the dye being used as well as the metal. Some metals do not require the additional step of dying to create a variety of colors. Anodized titanium naturally produces color, what the hue becomes, depends on the amount of electrical current used to anodize the piece.

- Once a metal has been dyed, hot water or steam, often mixed with nickel acetate, is used to seal the surface and to convert the oxide into its hydrated form. This process decreases bleeding and can improve corrosion resistance. Whether the color is a result of the process of anodizing or added, it is just one more reason anodized products are in such high demand.

Titanium Anodizing

Titanium is most often anodized for jewelry and other decorative applications. Anodized titanium is used in dental implants and is sometimes used in art, costume jewelry, body piercing jewelry, and wedding rings. However, the most commonly employed color anodization comes from organic and chemical dyes applied directly after the anodizing treatment. At the surface of a metal, anodizing increases the pore size of the chemical body which aids in soaking up the color and as a result retains color well.

The color that is formed will depend on the thickness of the oxide. It is caused by the interference of light reflecting off the oxide surface, with light traveling through it, and then reflecting off the underlying metal surface.

Magnesium Anodizing

Anodized magnesium is often used as a primer for paint and can be sealed with materials such as oil or wax. Even though zinc is rarely anodized, a process has been developed by the International Lead Zinc Organization, which produces hard, corrosion resistant anodized zinc in an olive-green color.

Aluminum Anodizing Images, Diagrams and Visual Concepts

Anodizing, an electrolytic passivation process which increases the thickness of the natural oxide film on surface which is durable, stable, and corrosion resistance..

Anodizing, an electrolytic passivation process which increases the thickness of the natural oxide film on surface which is durable, stable, and corrosion resistance..

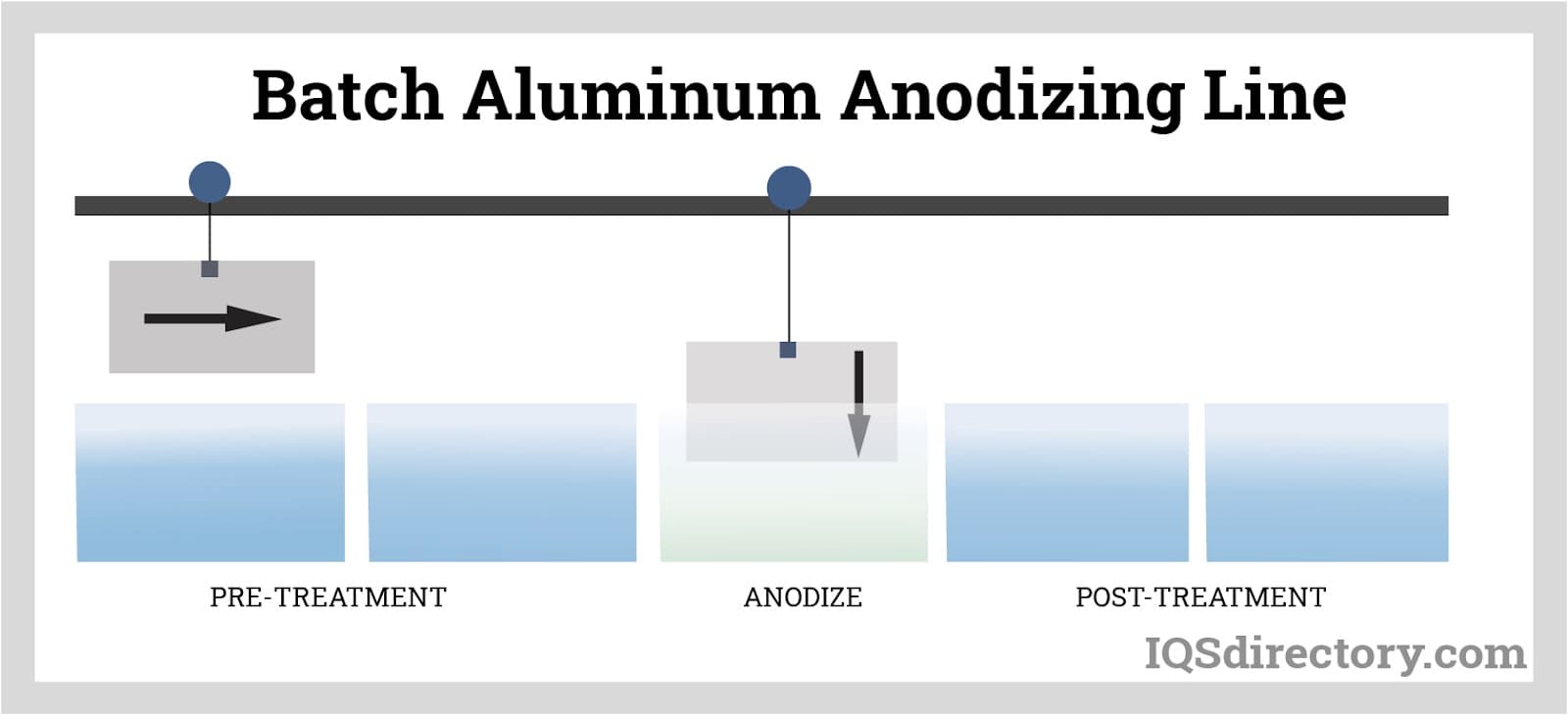

Batch anodizing, the parts are placed in a rack and immersed in a series of baths.

Batch anodizing, the parts are placed in a rack and immersed in a series of baths.

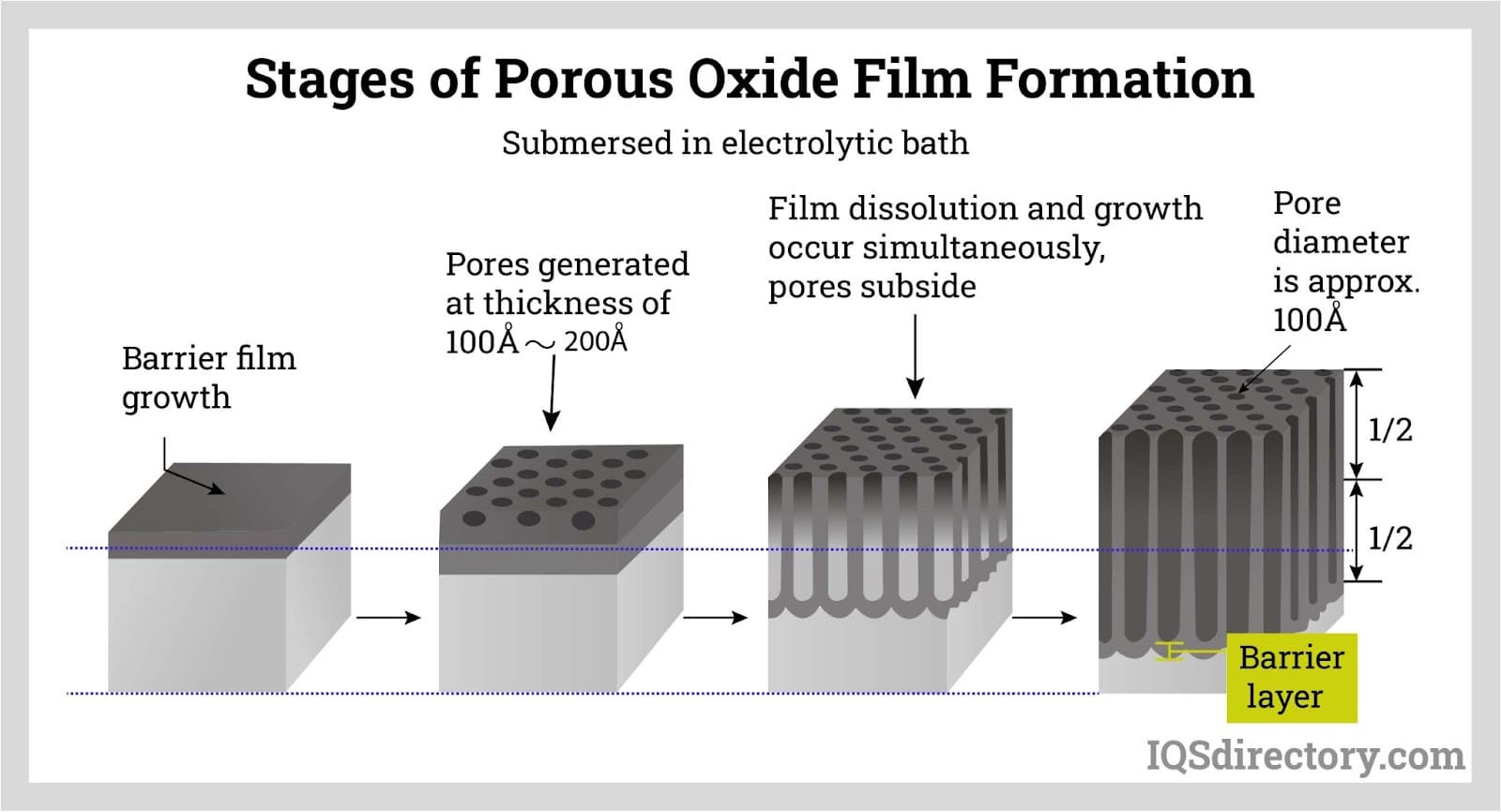

A porous oxide film is formed on the surface when grown in a dilute acidic solution and the thickness is proportional to the electrolysis time and voltage.

A porous oxide film is formed on the surface when grown in a dilute acidic solution and the thickness is proportional to the electrolysis time and voltage.

Dye or pigment fills the porous aluminum oxide film formed by anodized making the coating is durable and cannot be removed off the surface.

Dye or pigment fills the porous aluminum oxide film formed by anodized making the coating is durable and cannot be removed off the surface.

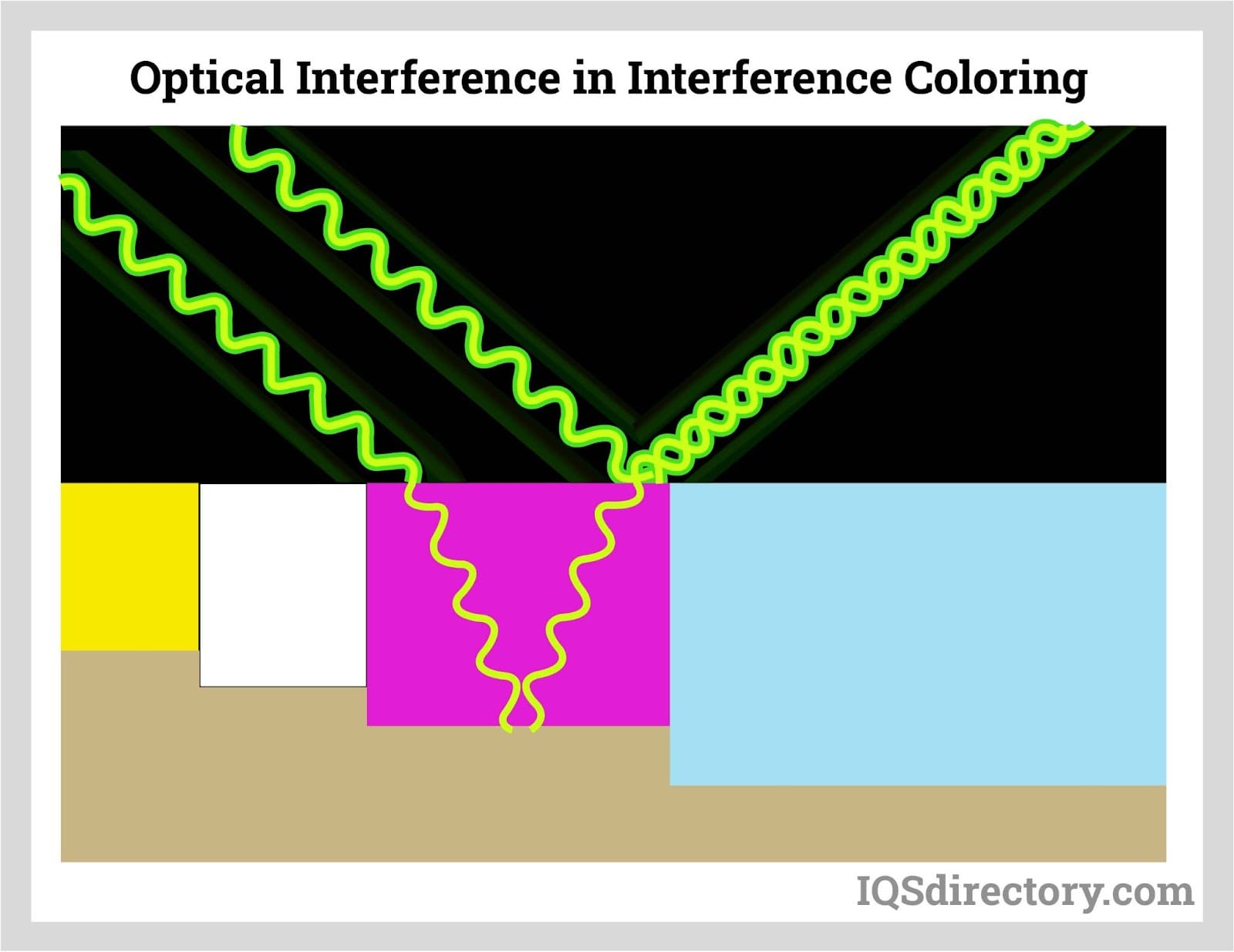

Interference coloring, the oxide film pores bases are enlarged to deposit more metallic ions electrolytically to produce light-fast colors.

Interference coloring, the oxide film pores bases are enlarged to deposit more metallic ions electrolytically to produce light-fast colors.

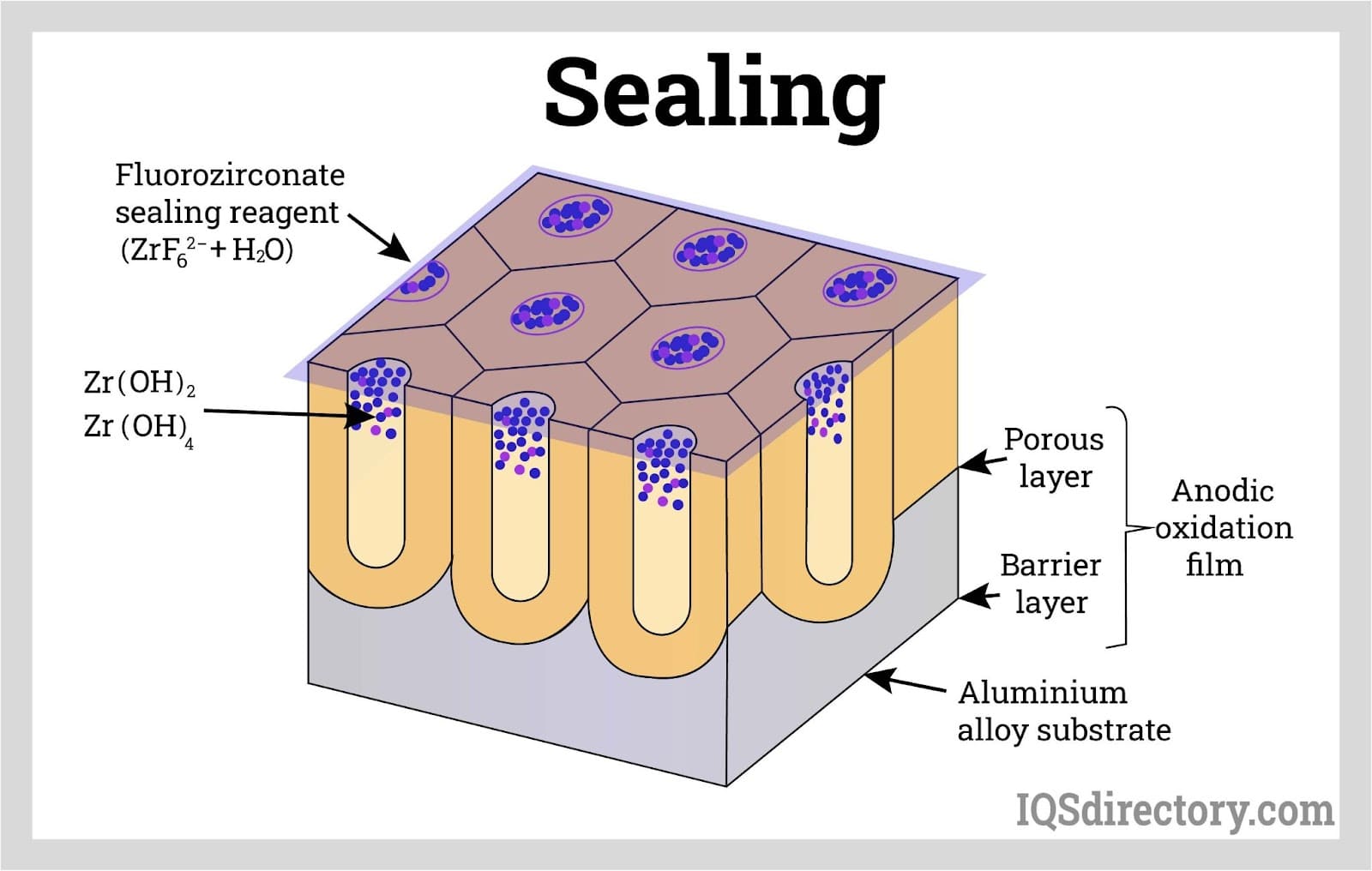

Sealing locks the absorbed dye, lubricant, or adhesive on the porous film which protects the porous film from corrosion, staining, and absorbing unwanted molecules.

Sealing locks the absorbed dye, lubricant, or adhesive on the porous film which protects the porous film from corrosion, staining, and absorbing unwanted molecules.

Anodizing creates a stable aluminum oxide layer fully integrated with the underlying aluminum substrate.

Anodizing creates a stable aluminum oxide layer fully integrated with the underlying aluminum substrate.

Aluminum Anodizing Types

- Anodizers

- Service providers of the anodizing process, creating anodized metals with increased wear and corrosion resistance.

- Anodized Aluminum

- Has undergone an electrolytic process in order to gain increased corrosion and wear-resistance, amongst many other benefits, due to the high susceptibility of un-treated aluminum alloys to corrosion.

- Anodized Metal

- A metallic element that has undergone an electrolytic passivation process known as anodizing in order to produce a layer of oxidation on the surface of the metal.

- Anodizing

- A technique used to coat the exterior of a metal with a protective film.

- Black Anodizing

- A process through which the surface of an anodized coated with a protective black dye.

- Bright Dip Anodizing

- Refers to the pretreatment step before anodizing, which takes place in a bath of acids and creates a bright, shiny finish.

- Chromate Conversion

- A process that provides corrosion resistance and makes the aluminum surface electrically conductive. It also provides a superior surface condition for the application of paints, powder coats and adhesives.

- Clear Anodizing

- Pre-oxidizes the aluminum surface for a clear, uniform finish.

- Color Anodizing

- When a colored coat is applied to the exterior of a metal.

- Custom Anodizing

- A process in which a small number of parts are uniquely anodized in order to achieve application-specific characteristics, such as the level of hardness or a desired color.

- Hard Anodizing

- A variant of anodizing. It produces similar results to standard anodized surfaces, but the thicker and denser hard anodic film limits the coloring results to dark tones.

- Sulfuric Acid Anodizing

- Provides a thin coating of aluminum oxide that is tightly bonded to the surface of the aluminum. This method offers corrosion resistance and aesthetic appeal, as well as makes the aluminum surface electrically non-conductive.

- Impregnation

- The filling of internal cracks, voids and corroded pockets, which would otherwise cause castings, forgings and powdered metal parts to leak.

- Titanium Anodizing

- Used most often in the jewelry segment of the industry, as it has less occurrence of skin allergy than any other metals.

Variations of the Aluminum Anodizing Process

Processes that fall under aluminum anodizing, all contain the essentials of the basic process. Often compared to applied coatings and electroplating, anodizing is technically an electrochemical conversion process because it converts the surface aluminum to aluminum oxide. There are different metals that may be anodized including titanium, magnesium, zinc, and aluminum is most popular.

As for lesser-known materials, anodized niobium and anodized tantalum are both used in much the same way as anodized titanium for decorative applications such as jewelry and even commemorative coins. The coating thickness of the oxide film for these two metals depends on the voltage of the anodizing current.

This short list of metals that are improved, rather than destroyed by the chemical acid bath that is anodization, is always topped with aluminum because it responds the best to the treatment.

Aluminum Anodizing Companies and Suppliers

IQS Directory provides a comprehensive list of aluminum anodizing companies and suppliers. Use our website to review and source top aluminum anodizing companies with roll over ads and detailed product descriptions.

Find aluminum anodizing companies that can design and provide aluminum anodizing services to your company’s specifications. Then contact the aluminum anodizing companies through our quick and easy request for quote form. Website links, company profile, locations, phone, product videos and product information are provided for each company. Access customer reviews and keep up to date with product new articles.

Whether you are looking for companies of aluminum anodizing services, the anodizing process, aluminum anodizing equipment, or customized aluminum anodizing of every type, this is the resource to use.

Aluminum Anodizing Terms

- Abrasion

- The process of using friction to grind and wear away at a surface.

- Activation

- Changing a metal surface into a chemically-active state.

- Alloy

- A substance with metallic properties composed of two or more chemical elements. At least one element must be metal.

- Alumina

- An intermediate step in the production of aluminum from bauxite.

- Anodizing Sheet

- A sheet that has suitable metallurgical characteristics and surface quality for the development of protective and decorative films by anodic oxidation processes.

- Bath

- The chemical environment in which the anodizing takes place.

- Brazing

- Joining metals together by flowing a layer of molten filler metal between them.

- Chemical Film

- The application of chromate conversion coating on aluminum.

- Corrosion

- The gradual chemical or electrochemical wearing of a surface. Also, this is the deterioration due to environmental forces.

- Cryolite

- A white mineral used in making aluminum

- Deburring

- The removal of burrs, sharp edges and fins by mechanical, chemical or electrochemical means.

- Edging

- Dressing metal edges by rolling, filling and drawing.

- Hardener

- An alloy of aluminum and at least one other metal that is used to make additions to molten aluminum.

- Impurities

- Undesirable elements in aluminum compounds.

- Inhibitor

- A substance used to reduce the rate of a chemical or electrochemical reaction, commonly corrosion or pickling.

- Melting Point

- The minimum temperature at which a metal will melt.

- Passivation

- Changing a chemically active metal into a passive state.

- Plating

- The process of laying a thin coat of metal on another.

- Pores

- Microscopic openings in an anodized surface, leading to a microscopic tube. Although porous, the anodized surface is very dense and hard.

- Rack

- The electrically-conductive device used to hold the parts to be anodized as they are lowered into the bath. Racks are made in different sizes, types and shapes to hold the large variety of parts and products encountered in anodizing.

- Refined Aluminum

- Aluminum that is in a very pure state.

- Smelt

- Fusing or melting ore in order to extract or refine the metal it contains.

- Striation

- Longitudinal lines that are not uniform, caused by uneven coating.

- Ultimate Strength

- The maximum stress a material can withstand.